Lrf Transformer

| LADLE REFINING FURNACE TRANSFORMERS

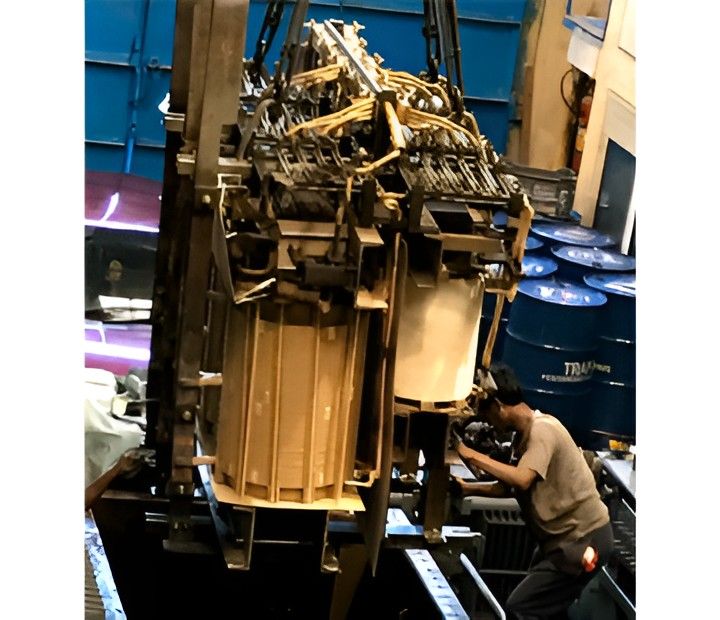

Ladle Refining Arc Furnace Transformer

The Ladle Refining Arc Furnace Transformer, commonly referred to as the LRF Transformer, is a critical component in the steel industry. These transformers support the ladle refining process in AC furnaces, ensuring stability during the arcing process between electrodes and molten steel.

High Current, Wide Voltage Range

Key Features:

- High Current Delivery: These transformers are capable of delivering high currents across a wide range of voltages, ensuring adaptability for various industrial needs.

- Robust Design: The transformers are meticulously engineered, showcasing robustness in both design and manufacturing, ensuring long-term reliability.

- Short-Circuit Resistance: LRF transformers are designed to withstand short-circuit conditions, making them highly reliable under challenging operational circumstances.

- Thermal Stress Management: Designed to handle high thermal stress, these transformers come with built-in cooling options to prevent overheating and ensure efficient operation.

Our Products

- Submerged Arc Furnace

Transformers - Electric Arc Furnace Transformer

(With Reactor And Without Reactor) - Ladle Refining Furnace

Transformer - Induction Furnace

Transformer - Rectifier/Converter Duty

Transformer - Solar Transformer

- Power Transformer

- Auxiliary Transformer

- Automatic Step Voltage Regulator

- Dry Type Transformer

- Earthing Transformer

- LT Panel Board

Technical Specifications:

The LRF Transformers are engineered to meet the high demands of the steel refining process:

- Compatibility: These transformers are fully compatible with AC furnaces, allowing seamless integration into ladle refining operations.

- High-Voltage Current Delivery: Capable of delivering high-voltage current, these transformers offer versatility for various applications.

- Short-Circuit Resistance: Specifically designed to endure frequent short circuits on the secondary side, ensuring reliable and safe operation.

- Thermal Stress Endurance: Equipped with multiple cooling options, these transformers are capable of dissipating heat effectively, preventing overheating during high-stress operations.

Benefits:

- The robust design, coupled with advanced features, ensures exceptional reliability and optimal performance in the ladle refining process.

- Short-circuit resistance and thermal stress management extend the lifespan of these transformers, making them ideal for high-demand applications.

Applications:

These transformers are primarily used in the steel industry, where they facilitate the ladle refining process, ensuring the production of high-quality steel products.

Quality and Compliance

- Certifications: IS/2026, IS/5553, IS/12977.

- Quality Assurance: We guarantee the highest quality standards for all our products, from design through production, labour, and quality assurance. Our transformers are engineered for durability and exceptional performance.

Support and Services

- Maintenance and Repair Services: Repair services are available exclusively for transformers manufactured by us.

Contact Details

Head Office

-

246/1k, Benaras Road,

J. D. Casting Compound,

Kona Check Post,

Howrah - 711114, West Bengal, India - +91 98318 23173 / +91 98302 52113

- kvamahesh@yahoo.com

Send Message

We would like to discuss:

kVA Process Transformers Pvt. Ltd. is a leading transformers manufacturing company in India. We are a proud established manufacturer of [Submerged Arc Furnace, Electric Arc Furnace, Ladle Refining Furnace, Induction Melting Furnace, and Power & Distribution] TRANSFORMERS of various types, grades and capacities.