Manufacturing Process

Transformers Technology & Design

At kVA Process Transformers Pvt. Ltd., with over a decade of experience, our expert team delivers optimized, reliable, and cost-effective transformer designs that meet evolving market demands. We adhere to international standards such as BIS, IEC, BS, ANSI, and NEMA, ensuring full compliance and interoperability.

Using advanced CAD technology, we provide fast design reviews and supply final drawings digitally and in print upon request. Our designs comprehensively address key electrical and mechanical parameters, including losses, impedance, temperature rise, and pressure withstand capabilities.

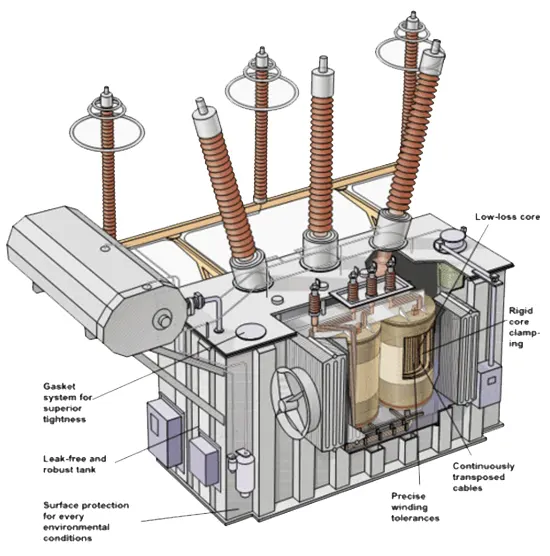

Windings

Our transformer windings are designed for optimal mechanical, thermal, and electrical performance. Made from high-conductivity electrolytic copper with paper insulation, they meet both Indian and international standards.

Skilled technicians wind the coils in a dust-free, temperature-controlled environment. Cooling ducts (axial & radial) minimize hot spots and prolong insulation life.

Techniques like conductor transposition improve current distribution and reduce losses. Low-voltage windings use multi-layer coils for high current, while high-voltage windings feature durable disc coils for stress resistance.

Core Construction

The transformer core is vital to performance, and we use premium Cold Rolled Grain Oriented (CRGO) silicon steel to ensure low losses and high efficiency. Laminations are precisely cut to minimize air gaps and maximize magnetic flux flow.

We select core materials and construction types—such as butt-lap, miter, or step-lap miter—based on loss requirements. Laminations are burr-free, fully annealed, and coated to reduce eddy currents. Their thin profile (0.23–0.27 mm) ensures low noise and excitation current.

Core & Coil Assembly

At kVA Process, we use high-grade precompressed pressboard and kraft paper (as per IS:1576) for insulation, along with Permali wood for added mechanical strength. Insulating materials are tested for high dielectric performance.

LV windings are placed near the core over insulating cylinders with oil ducts, while HV windings are co-axially assembled with LV windings. ‘T’-shaped spacers ensure added firmness, and densified wood rings provide precise coil alignment. Angled rings between LV and HV windings help reduce voltage stress.

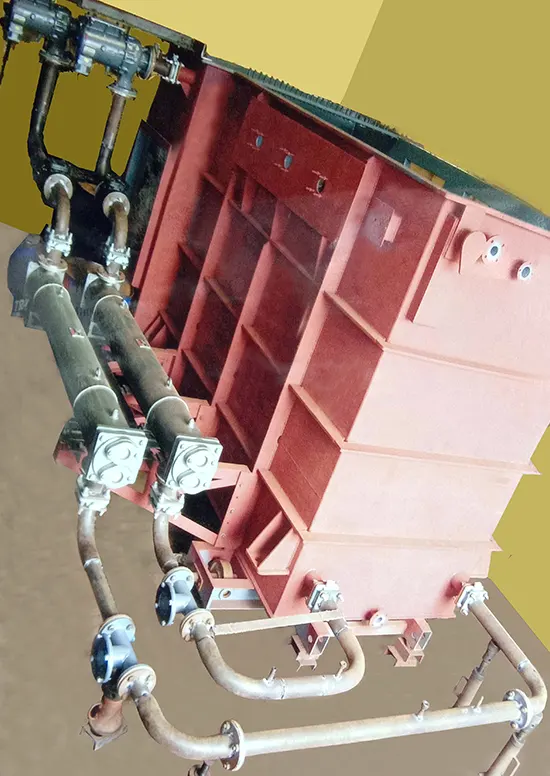

Tank Construction

All our tanks are fabricated with high grade tested mild steel. The design of the tanks incorporated adequate wall & thickness so as to withstand the pressure build up in the tank.

Protection of active part in transformer is very important. While achieving the optimized size of transformer to suit the site condition for installation, the role of the tank is to protect the active part. The tank is manufactured to have sufficient strength to withstand internal & external faults that may occur during operation.

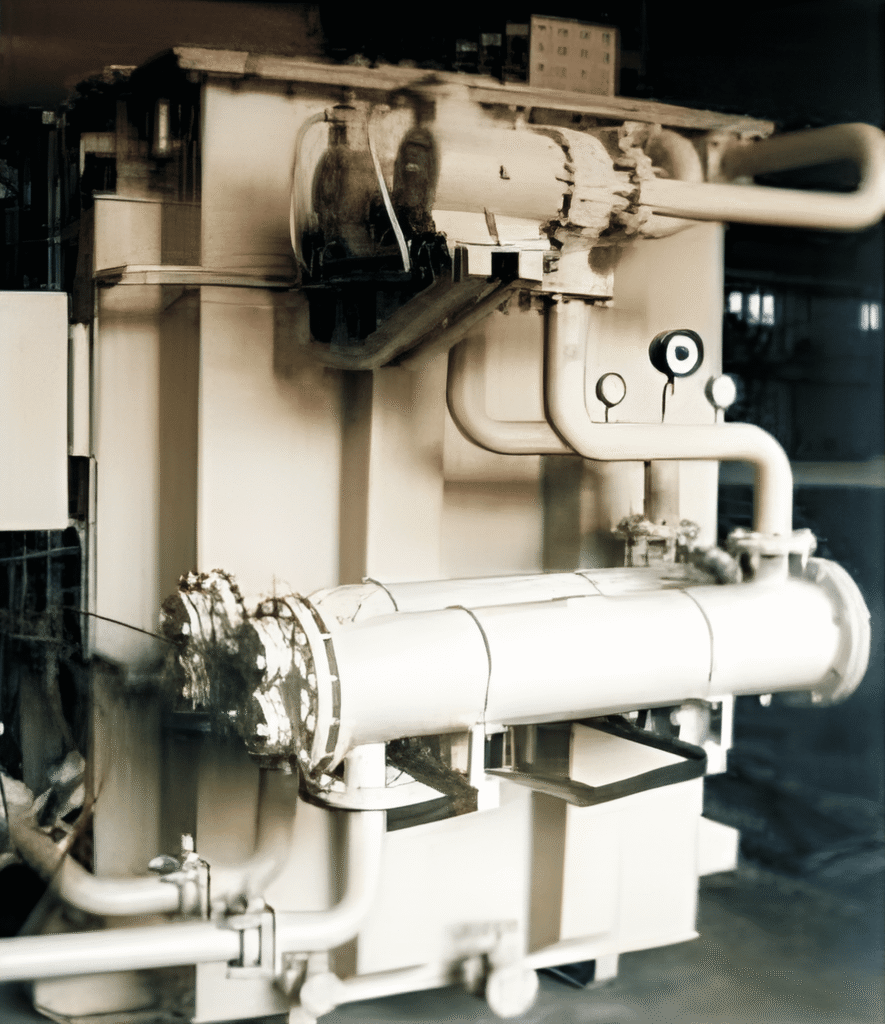

Cooling System

kVA Process designs and manufactures transformers with various cooling methods based on customer requirements and site conditions.

ONAN: Uses pressed steel radiators for natural air cooling, offering a large surface area for effective heat dissipation.

ONAF: Adds cooling fans near radiators to enhance airflow and cooling efficiency.

OFWF: Uses heat exchangers, oil pumps, and flow/pressure meters for water-cooled systems, ideal for high-load conditions (up to 150%).

Transformer Oil

We use premium-grade insulating oil to ensure optimal performance and longevity of our transformers. Selected for its low viscosity and high oxidation resistance, the oil efficiently dissipates heat and minimizes sludge and acid formation.

Each batch ensures rigorous testing for moisture content, dielectric strength, and chemical stability, in full compliance with IS: 335/1993 standards. We primarily use TRANSOL EHV oil by SAVITA, a trusted brand known for its purity and stability.

Testing Facilities

At kVA Process Transformers Pvt. Ltd., our state-of-the-art testing laboratory is equipped with advanced digital and computerized instruments to perform routine tests on transformers up to 25 MVA and 132 kV in accordance with IS and IEC standards.

We conduct the following precise tests:

- • Winding Resistance Measurement

- • Voltage Ratio and Vector Group Verification

- • Impedance Voltage and Load Loss Measurement

- • No-Load Loss and Excitation Current Measurement

- • Insulation Resistance Measurement

- • Dielectric Strength Test

Contact Details

Head Office

J. D. Casting Compound,

Kona Check Post,

Howrah - 711114, West Bengal, India

kvamahesh@yahoo.com

Send Message

We would like to discuss: